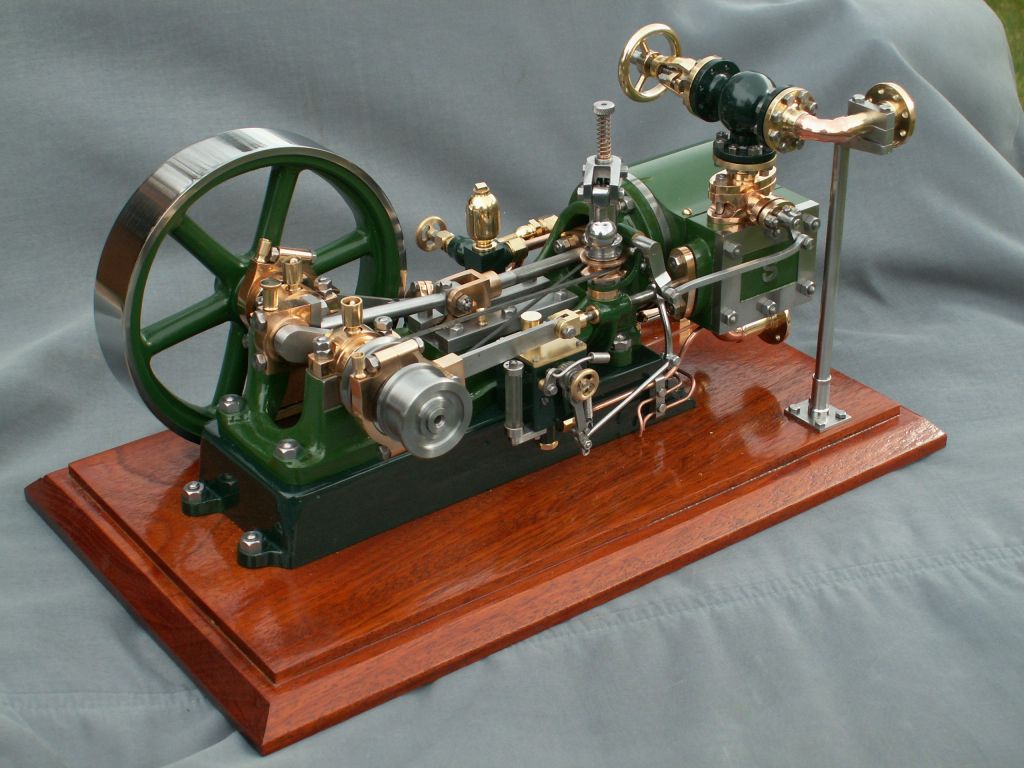

The Model Steam Engine

My Grandfather built two model steam engines which I inherited from my Dad. When I was a pre-teen these engines were a source of endless fascination for me. One is a two-cylinder vertical engine for a model boat he built and the other is a stationary one-cylinder single action horizontal engine.

One day when I was playing around with the engines, I decided it would be interesting to build a smaller version of the horizontal single action engine out of scrap metal from the basement stash. I understood the general principle of the single action steam engine but was somewhat confused how the valve actually worked.

I thought I would fool around with the thing and figure it out. I had my Dad’s permission to use the metal working lathe and drill press so I decided it would be a good project for me to mess around with. The cylinder, flywheel and shafts were straightforward lathe projects, but the valve was a bit of a mystery.

I realized it had to be constructed so one port would let the steam into the cylinder and another would be needed to let the steam out. They also needed to be timed so that this would occur the instant the piston reversed direction. It also had to be made using only the lathe and drill press since these were the only two machines I had to work with.

Eventually, I figured it out after many false starts, and I used up a lot of scrap metal before the engine would run beyond one revolution. By trial and error, it finally came together and ran smoothly.

Years later I became aware of the saying attributed to Leonardo da Vinci, “The mind learns from the hands”. But this was probably my first actual hands on experience based on this principle. There is no substitute for building one; thought experiments are all well and good but fundamental understanding comes from building, experimenting, modifying and experimenting some more.

Many years later, when I was a self-employed chemical engineer, I worked with a mechanical engineer, Richard Keener, who had a complete machine shop in his garage and built some of the machinery I designed for my clients.

We were working together in my basement shop one day and he spotted the model steam engine I had built. He asked me about it, and I told him it’s a steam engine I built when I was a kid. He asked, “How old where you when you built it?” I told him “I was about twelve or thirteen.” He replied. “Christ, you’re a damn prodigy!” I told him “No, I just had a good example to follow.” But it was a great compliment from a guy I had a lot of respect for. A man that designed and built his own turbo charger for his vintage Mercedes Benz.

He also had a vintage 1953 MG TD sports car his shop completely disassembled. It was now in a heap of parts piled on the floor. Hanging on the wall over the pile of parts was a photo of Richard at the wheel in Watkin’s Glen, New York setting the track speed record. He was negotiating the last turn with the car healed over on two wheels. I asked him when he was going to put it back together? He told me eventually. He called it his future retirement project.

I don’t believe he ever retired or ever got around to that project. I would have loved to tackle the rebuild. But there was no way he would part with that old pile of parts. I didn’t understand it then, but I do now.

1953 MG TD

The Unfinished Gasoline Engine

When I was in high school, I took a college prep program but also took a class in machine shop. With my marginal grades, my Mom encouraged me to take the shop class as a backup plan. She encouraged me to “learn a trade” so I could make a living if I didn’t get into college. Having worked with machinery at home from the time I could barely look over the top of the workbench it was obvious to the shop teacher that I knew my way around a machine shop. He was an excellent teacher and provided me with a great deal of encouragement.

In the senior year each student had to do a shop project of his or her own choosing that would count for fifty percent of their final grade. I already conquered the steam engine project at home several years earlier, so I decided to take it up a level and build a model of a one-cylinder gasoline engine.

I worked the entire school year on that project but near the end screwed up machining the cylinder and never finished it. I still regret that I gave up too soon. Nevertheless, the shop teacher was impressed, gave me a good grade, and more importantly recommended me to a local machine shop, Heller Machine and Tool, for a job as a tool and die maker apprentice.

This was my first full time job after I graduated from high school. And so, I started the apprenticeship program at Heller Machine and Tool Company in Union, New Jersey. It was a formal four-year program sponsored by a Government grant for my employer. I started for minimum wage of $1.25 per hour. Take home pay was $42.50 per week. It was a great job. I loved it and was good at it. Part of the program was a requirement to take certain courses in the evenings at an approved technical school, specifically algebra and trigonometry.

For the first time since my early childhood, I was truly academically motivated. I researched the options and discovered I could take the required math courses at Union County College, a local Community College located nearby in Cranford, New Jersey. I eagerly signed up for the courses and at the end of the first semester I received an A in both courses. The first time I ever got two A’s back to back was in those two math courses. I signed up for the next semester and Heller Machine reimbursed the tuition.

Once I started with the program, I became even more motivated. There was none of the bullshit there had been in grammar and high school. Either you showed up for classes and got the benefit or you didn’t and dropped out or flunked out. I not only showed up, I was energized.

I didn’t want to lose my Toolmaker’s job and actually found the higher math a really gratifying challenge. I finally hit my stride. I was doing well in the curriculum and made a commitment to continue with the program and obtain a two-year associates degree which would qualify me to apply later to a four-year university. It wasn’t part of the apprenticeship program, but I was able to convince Cliff Heller, the owner of Heller Machine, to support my plan and reimburse my tuition for the Community College program.

I aced all the courses in Junior College and began to consider majoring at a four-year university in engineering. I never actually completed my Associate’s degree but after a year and a half in Community College decided to transfer to Newark College of Engineering (NCE). That was the plan if I could get accepted. I had taken the SAT’s in high school and scored in the top ten percentiles. I then took the entrance exam for NCE and achieved a very high score. I was always good at tests, I was just never good at doing the homework assignments. Based on the SAT’s, the NCE entrance exam and my grades in Community College I was accepted at NCE and entered the evening program majoring in mechanical engineering.

Over the next year, I continued evening classes in the mechanical engineering program. I then took a required course in fundamentals of chemistry, an introductory chemistry course for mechanical engineering students. This was it! I had another epiphany. I loved this stuff and it occurred to me I was enrolled in the wrong program.

Chemical engineering was the right place for me. The following semester I switched from mechanical to chemical engineering and fortunately was able to transfer most of the credits I earned as an ME student to the ChE program.

So long, good luck and have a nice day!